14-November-24

Antennas are the unsung heroes of the modern tech world. They power our smartphones, enable satellite communications, and make IoT networks possible. But designing antennas that meet the growing demand for higher efficiency, smaller size, and broader bandwidth is no small feat.

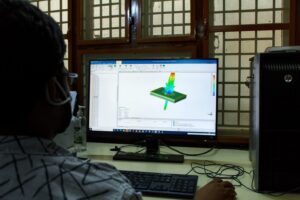

This is where antenna simulations come into play. Instead of relying solely on a trial-and-error approach with physical prototypes, engineers can now use advanced simulation software to test and optimize designs in a virtual space. Software such as HFSS (High-Frequency Structure Simulator) and CST Microwave Studio have become essential tools in an engineer’s arsenal.

Why Simulations? Imagine trying to build the perfect antenna without any prior testing. The cost, time, and effort would be immense. Simulations allow engineers to model how an antenna will perform under different conditions, analyzing parameters like return loss, directivity, and radiation pattern with pinpoint accuracy.

Take, for example, the design of antennas for 5G networks. With their higher frequency bands, these antennas need to be incredibly precise. Through simulations, engineers can tweak designs, identify performance bottlenecks, and ensure optimal performance before a single piece of hardware is built.

The future of antenna design is only becoming more sophisticated, with AI-driven simulations making the process faster and more efficient than ever before.

Here, we like to give some insights into antenna solutions and challenges for wireless products.

The performance of integrated antennas in your products strongly depends on several factors. Some of these are listed as follows:

An off-the-shelf LTE antenna optimized for a large PCB (140 mm x 70 mm) won’t work as per its datasheet when installed on a smaller PCB system (per se 60 mm x 50 mm). One of the biggest mistakes wireless device manufacturers make is to follow antenna vendors’ datasheets blindly, thinking that the antenna is well-tuned. There is a massive difference between a well-tuned antenna and one customer assumes it’s well-tuned.

Dielectric properties of plastic materials do impact antenna tuning. Thus the choice of material is essential for optimal RF performance. The impact of housing materials, their shape, and size on antenna performance can be easily studied using state of the art simulation tools.

Deciding the position of antennas on the system ground plane should start at the beginning of the project. For example, LTE antennas or any sub-GHz antennas use the ground plane as the main radiating element and need a more extended ground plane for optimal performance. Thus typically, they are located on the short edge of the system PCB. Antenna positions also need to take into consideration of the user’s head and hand views as well. If the antenna is blocked by the user’s hand, it will result in poor on-field performance; one good example is the new iPhone death grip. The user finger covers the antenna slot, essentially detuning the antenna.

An expensive and well marketed off the shelf antenna doesn’t necessarily bring the best antenna performance to your device; a simple, well designed, and tuned PCB antenna might work well for your device. It will reduce your BOM and extra unnecessary assembling costs. It’s not which antenna is used; instead of how well an antenna is tuned to the customer device is more critical to achieving the best wireless performance.

Modern 3D antenna/RF simulation tools enable us to design an optimized antenna solution for your product, maximizing the RF performance and device range. Thus it ensured stable wireless communication and risk mitigation in rather expensive certification tests.

© 2026 CoreIoT. All Right Reserved.

Designed & Developed by  Innov Touch Technologies Pvt Ltd.

Innov Touch Technologies Pvt Ltd.